The full sized version of these pictures can be viewed by right clicking on the picture and selecting "VIEW IMAGE", then use your browser back button to return to the the web page...

The bike started life as an 81 XLH. One of the goals of this project was to hand fabricate as many components as possible. As a result the list of modifications is long. So I'll just start at the front of the bike and work through to the rear.

The front wheel is a 21" Borrani rim laced to a NOS Kosman hub with stainless steel spokes. The Kosman hub has metric bearings so of course the HD axle wouldn't fit. The axle was machined down to fit the metric bearings and the wheel spacers had to be made. The front wheel has double discs mated to an old HD double disc lower legs. As expected the HD caliper mounts were in the wrong place to work with the Grimeca calipers, so the HD mounts were turned off the legs and the Grimeca calipers mounted to where HD used to bolt the fender on. The caliper mounting plates were fabricated. Moving on up I also made the triple clamps and center post, lets face it the stock XL clamps are just plane ugly. I also made the little pillow blocks for securing the brake lines and throttle cables. The handle bars were widened and made taller.

Moving back a little, all the ugly humps and fork lock provisions were ground off the area below the neck. Those extra holes on the neck casting where people usually bolt on an oil cooler had to be welded in and ground down.

A new gas tank with the left side petcock was installed. I did have to cut the rear tank mount off the new tank and relocate it to line up with the hole in the frame. I also made special bushings to rubber mount the tank.

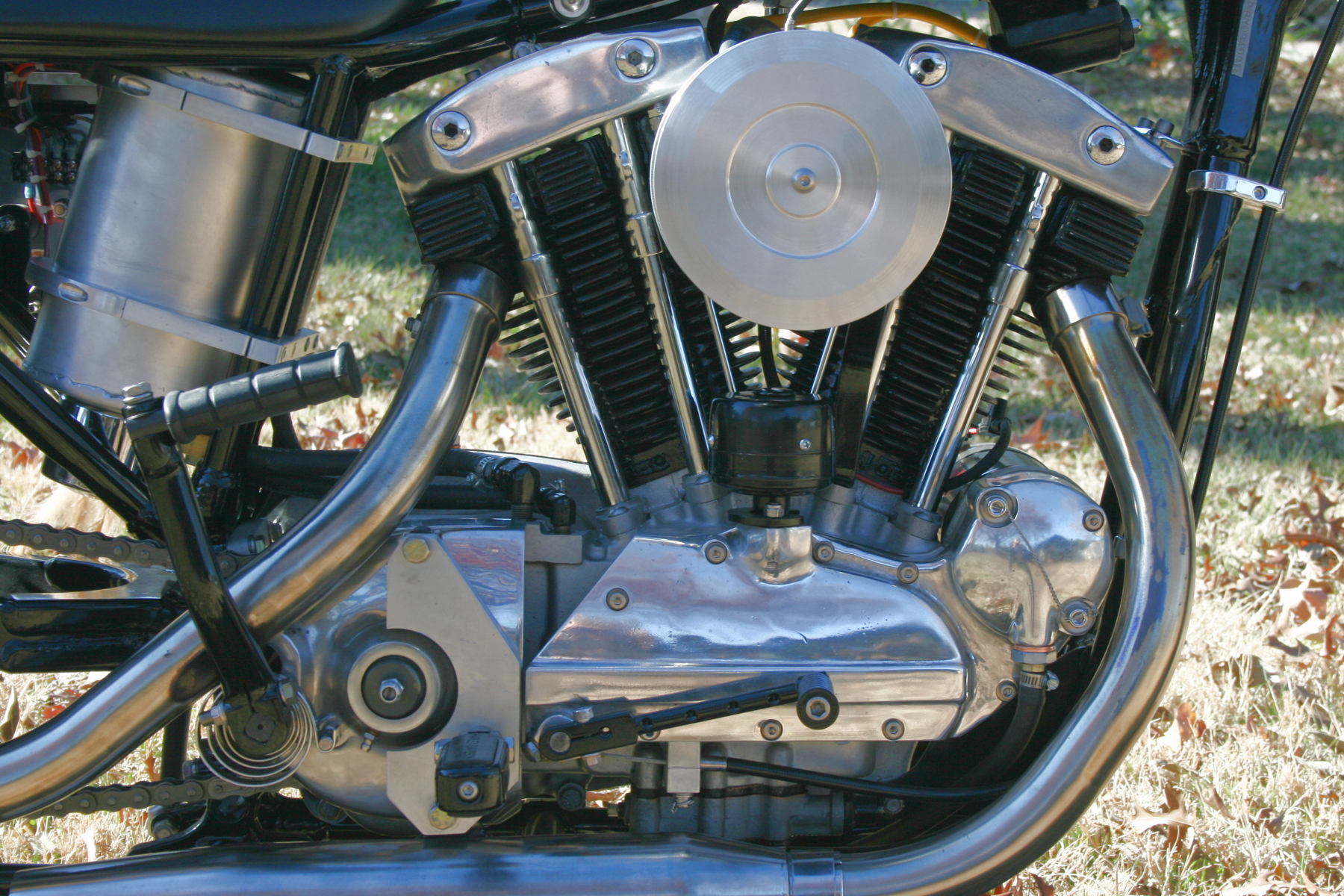

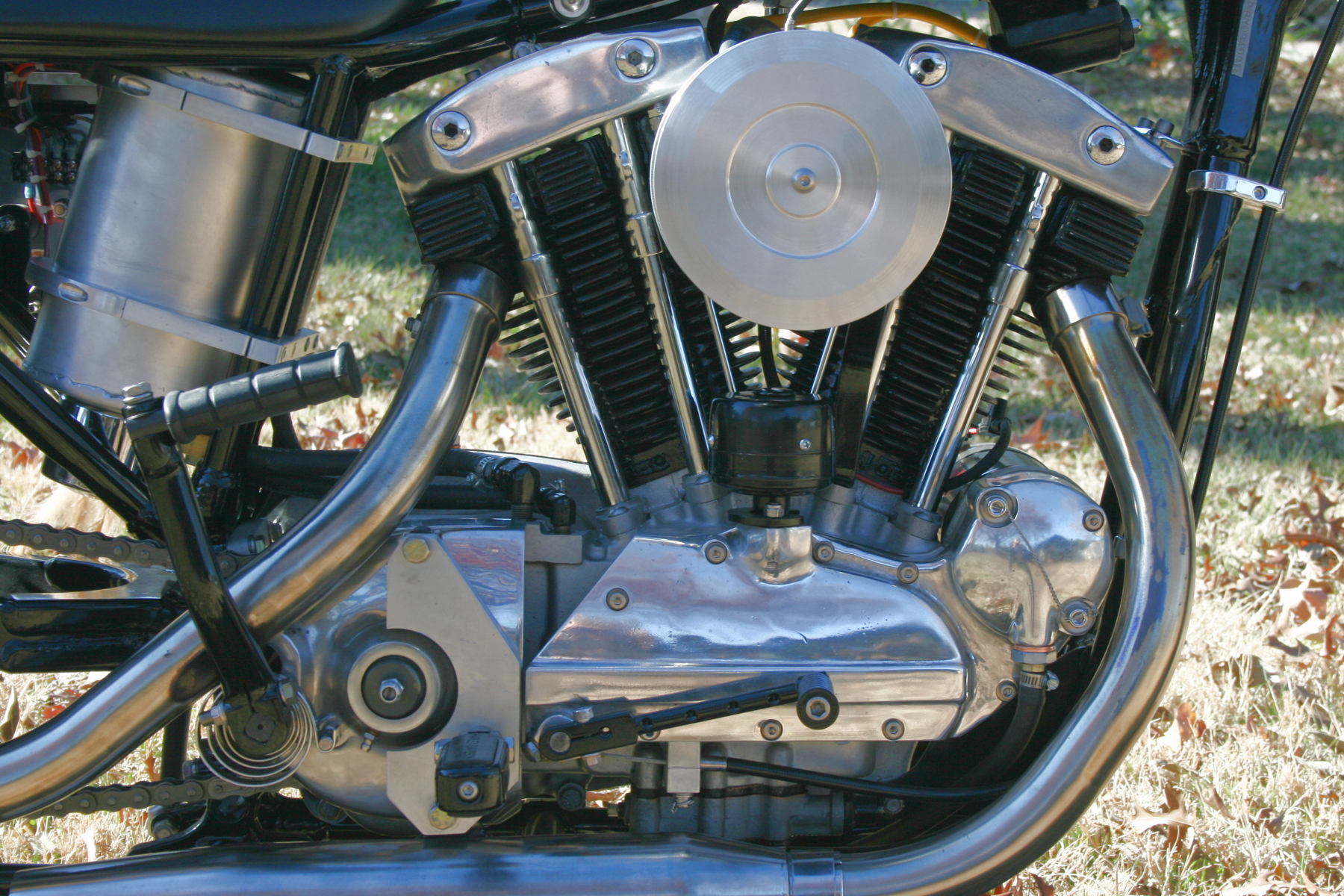

Moving down, the 81 frame had no provisions for mounting foot pegs, they were mounted to the engine. The early style engine I was using had no provisions for foot pegs, or left side rear disk brake, hence the heavy aluminum brackets on either side of the engine for mounting the pegs and brake pedal. I made the brake pedal and linkage as well as the gear shift lever.

I also made the oil tank and its mounting system. I wanted it vertically mounted just to be different. There is an oil filter integral to the tank. The tank has internal passages to direct the oil through the filter. The oil out of the filter flows up through a vertical stand pipe inside the tank so as to keep the oil in the tank from gravity feeding back into the engine through the return section of the pump. The mounting plates were trickier to make than they look because the rear frame tubes are not parallel, they converge, so the holes for mounting the plates had to bored at just exactly the right angle to match the frame tubes. The mounting plates also have a couple of holes drilled in them to keep the vent hose and brake light switch wire routing nice and neat.

The seat is a LePera seat pan that was cut in two and lengthened about two inches, it was also reshaped and re-contoured to match the eight inch wide fender. The bare pan was powder coated (as was everything else on the bike that is black) and shipped back to LePera to be covered. They did a great job, I really like it. The fender had to be slightly narrowed to fit the frame and the front of it was further tapered and narrowed to fit and fill the area behind the oil tank. The seat is held down with a big ol' knob I milled out of billet, the seat has to be easy on - easy off because the fill cap for the oil tank is under the seat.

The battery holder is a milled and welded assembly, rubber mounted to brackets welded to the frame. The battery hold down bolt is drilled for a safety pin, also for easy on - easy off. My old lady, I mean sweet and loving wife, gave me a little dream catcher for good luck, it is hanging off the safety pin in the bolt. Some guys might not like the battery hanging exposed on the side of the frame, but, fuck 'em, I like all the bits and pieces being easily accessible. And, guess what, its my bike.

The swingarm has been cut in two and lengthened two inches.

All those weird lumps where Harley mounted the stock rear fender brackets were cut off and the frame tubes were extended as they had to be to keep the fender centered over the rear wheel which is now sitting two inches farther aft than it used to be cause of the lengthened swingarm. The shocks are two inches shorter than stock. The chain guard has a reinforcements weld on the back side because every one of them I've ever seen is cracked.

The rear wheel is also a NOS Kosman hub with stainless steel spokes laced to an 18" Akront alloy wheel. And of course these metric bearings didn't match up with the ¾" HD axle either so I had to make spacers and adapters to make the hub fit the axle. This wheel is also fitted with a Grimeca disc brake.

Bringing up the rear end, the license plate/brake light was milled out of a chunk aluminum.

The engine is basically stock, intended to be easy starting and easy to take care of; no hot cams, no high compression and regular point ignition. My hypo motor is in Fear No Evo and it fills my need for speed. I did mill the cam cover down and fabricate an anchor point for the clutch cable.

This bike has a Mikuni round slide I got from a friend, I think it is a VM38. Anyway it works great, it was 40 degrees F down yonder here in Texas the other day and the bike started easily on a couple of kicks. So far I see no need to rejet. All I had to do was set the idle speed and mixture. I couldn't find an air cleaner that I liked, so I made my own, also milled from a chunk of billet.

There really is too much to list as far as mods and hand made parts. I can honestly state that there are no "bolt on" parts, every thing was either made by me or modified. Every part that I did buy ended up being somehow modified before I would or could use it. Stainless steel fasteners are used throughout, the larger bolts had the heads turned down on a lathe to make them smaller and remove head markings. You may notice a fair amount of billet aluminum on this bike. As it happens I live about 15 miles up the road from the former American Iron Horse factory. I went to their going out of business sale, and there was tons of really nice stuff for sale, but all my meager budget could afford was a pile of their billet aluminum raw stock. So in a way, this bike may truly be the last American Iron Horse.

So, call this one done. The next project is sitting on the bench, it will be a bone stock, restored 79 XLH, it will be for sale when its done. I'll take your order now. For a 50% deposit you can order your options such as color, tires and custom details.

This bike is for sale, $20,000.00...

The full sized version of these pictures can be viewed by right clicking on the picture and selecting "VIEW IMAGE", then use your browser back button to return to the the web page...

Buy and Sell Ironheads - Buy and Sell Ironhead Parts - Rebuild Ironheads - Specialty Work - Wheel Building and Lacing - Wiring - Engine Rebuilding - Transmission Rebuilding - Flywheel Trueing - Line Lap Case Bearing Races - Lap Rod Races - Valve Jobs - Install Hardened Seats - Cylinder Boring - Heliarc Welding - Lathe and Mill Work - Powder Coating

All work is performed in house in a fully equipped shop.

IronHeadCycle LLC

North Texas

United States of America

Phone: 940-297-5009

Send a Message to IronHeadCycle